Product Categories

Plastic Injection Components

Plastic Injection Components- PVC Fittings injection

- PVC Non metallic LiquidConnector

- Plastic Injection parts

- Plastic Injection parts Motor Frame

- Plastic Injection Control Handle

- Injection Charger Base Accessories

- Plastic Ups Drive Housing

- Plastic Injection Accessories

- Plastic Injection Clear Housing

- Plastic Injection Molded Connector Accessories

- Plastic Injection Curve Joint Fittings

Metal Stamping Components

Metal Stamping Components- Metal stamping TV Top Metal Box

- Metal Stamping Accessories

- Metal stamping STB Metal Box

- Metal stamping TV Metal Case

- Metal stamping Power Adapter Metal Housing

- Metal stamping Power Metal Stamping Plate Housing

- Metal stamping Power Metal Stamping Housing

- Metal stamping Led driver Metal Base

- Metal stamping Led Driver Metal Housing

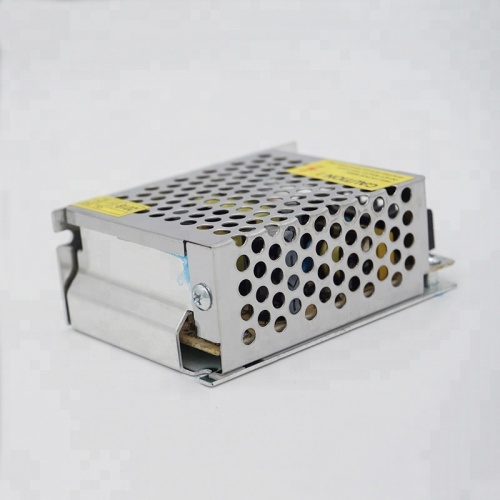

- Switching power Metal Stamping Parts

- Metal stamping Precision Copper Stamping Parts

- Metal Stamping Spring Fittings

- Metal stamping AMPLIFIERS Metal Chassis & Panel

- Metal stamping Audio Metal Chassis Panel

- EMI / RFI Shielding

Online Service

- Contact Person: Mr. Alan Nong

- View Contact Details

News

What impact does metal stamping technology have on product quality?

Metal Stamping technology is a commonly used manufacturing process that can be used to produce a variety of metal stamped parts. The quality of Metal stamping technology directly affects the performance, appearance and life of the product. Therefore, all aspects of the manufacturing process must be strictly controlled to ensure the quality of the final product.

1. Surface quality. Through stamping processing, the surface of the product can be smoothed, surface defects and oxidation can be reduced, and the aesthetics and corrosion resistance of Metal Stamping Parts can be improved. Reasonable selection of stamping mold and punch machine parameters, and adjustment of appropriate temperature and pressure can effectively avoid problems such as deformation, defects, and scratches on the product surface, and ensure product surface finish and flatness.

2. Dimensional accuracy. By controlling factors such as material stretch, shrinkage and rebound during the stamping process, the dimensional accuracy and repeatability of the product can be effectively improved to meet the accuracy standards required by customers and ensure the interchangeability and stability of the product during assembly and use. sex. .

3. Strength and wear resistance. Reasonable selection of metal materials and adjustment of stamping parameters can improve the material properties of the product, increase the strength and hardness of the product, and enhance the wear resistance and durability of the product. By processing different metal processes, the elastic deformation and strength optimization of the product can also be achieved to meet the requirements of the product in different environments and usage conditions.

3. Strength and wear resistance. Reasonable selection of metal materials and adjustment of stamping parameters can improve the material properties of the product, increase the strength and hardness of the product, and enhance the wear resistance and durability of the product. By processing different metal processes, the elastic deformation and strength optimization of the product can also be achieved to meet the requirements of the product in different environments and usage conditions.

4. Cost efficiency. Reasonable design of stamping molds and selection of Metal Stamping Tools can reduce product manufacturing costs and labor costs, and improve production efficiency and capacity utilization. Through automated control and intelligent equipment, production automation and assembly line operations can also be realized, improving production efficiency and stability, and reducing production costs and energy consumption.

Based on the above, it can be seen that only by scientifically and rationally controlling the metal stamping process and strictly implementing the quality management system can we produce high-quality, high-performance metal products to meet market demand and maintain competitiveness.

1. Surface quality. Through stamping processing, the surface of the product can be smoothed, surface defects and oxidation can be reduced, and the aesthetics and corrosion resistance of Metal Stamping Parts can be improved. Reasonable selection of stamping mold and punch machine parameters, and adjustment of appropriate temperature and pressure can effectively avoid problems such as deformation, defects, and scratches on the product surface, and ensure product surface finish and flatness.

2. Dimensional accuracy. By controlling factors such as material stretch, shrinkage and rebound during the stamping process, the dimensional accuracy and repeatability of the product can be effectively improved to meet the accuracy standards required by customers and ensure the interchangeability and stability of the product during assembly and use. sex. .

4. Cost efficiency. Reasonable design of stamping molds and selection of Metal Stamping Tools can reduce product manufacturing costs and labor costs, and improve production efficiency and capacity utilization. Through automated control and intelligent equipment, production automation and assembly line operations can also be realized, improving production efficiency and stability, and reducing production costs and energy consumption.

Based on the above, it can be seen that only by scientifically and rationally controlling the metal stamping process and strictly implementing the quality management system can we produce high-quality, high-performance metal products to meet market demand and maintain competitiveness.